Blog

How to choose cummins diesel generator smoke pipe insulation material

In large public buildings, in order to meet the requirements of fire fighting, emergency lighting, process production, and ensure the safety of people’s life and property, emergency diesel generator sets are set up. High temperature smoke tube is an important part of generator smoke tube, but its installation process is often ignored. The wrong installation will cause the deformation of the bracket, reduce the efficiency of the generator, and lead to safety accidents and other adverse consequences.

There are two commonly used ways of laying smoke exhaust pipes:

(1) Flat overhead laying, the advantage is less turning, small resistance, the disadvantage is to increase the indoor heat dissipation to increase the temperature of the machine room;

(2) In the trench laying, the advantage is that the indoor heat dissipation is small, the disadvantage is that the exhaust pipe turns more, the resistance is relatively large. In high-rise construction qiongqi is commonly used in horizontal frame narrow installation. The exhaust pipe should be led out separately to minimize bends. The exhaust temperature is 350 ~ 5500C. In order to prevent scald and reduce radiant heat, the exhaust pipe should be insulated. Generally, there is no ceiling in the machine room, which is 50 ~ 60 degrees, because the material of the top is small combustion or combustion body. It should be noted that there is a certain distance from other pipelines in the ceiling.

Many are in the diesel generator room outside the wall directly do a well to the outside of the stainless steel pipe. Insulate the section through the room. It doesn’t matter what material you use, as long as it’s strong. Heat preservation must be done, pay attention to the tube well set drainage, can use ordinary welded pipe, outsourcing a certain thickness of insulation cotton, through the room that section to see what the room is ten, if it is the power distribution room that should be careful, good to avoid, if it is the top of other rooms, can directly package cotton, outsourcing tin foil.

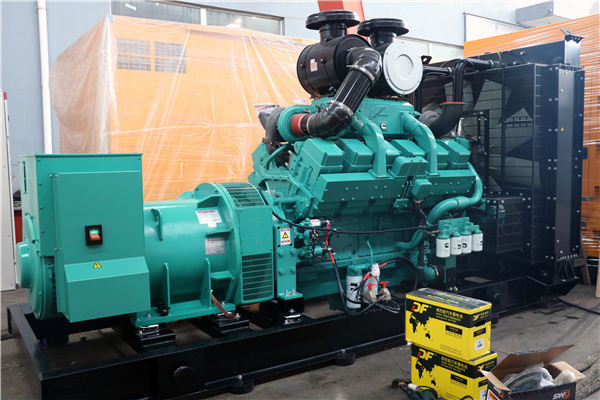

Jiangsu Meao Power Technology Co., Ltd. focuses on the development and manufacture of diesel generator sets, and has accumulated rich experience in manufacturing and service in this field. As a professional generator manufacturer, MEAOPOWER attaches great importance to product development, innovation and service quality, and maintains close strategic cooperation with famous domestic and international enterprises such as Cummins, Perkins, Doosan, Yuchai, Weichai, Shangchai, Wuxi Wandi, Lillesomer, Stanford, Marathon and so on.