Blog

How to clean the cylinder of Cummins generator set?

Cummins generator set cylinder is the main structure of the internal combustion engine, is to install all the parts and accessories of the supporting frame; Ensure that all moving parts in the process of work to maintain accurate mutual position; Set the internal cooling and lubrication channels of the internal combustion engine to ensure the cooling and lubrication necessary for the normal operation of all parts; Install each auxiliary system component of internal combustion engine, support the whole weight of internal combustion engine. Before installing other parts and accessories, the main installation surface, friction surface, lubricating oil channel and other key parts should have high cleanliness to ensure the assembly and operation quality of the whole machine. Therefore, it is of great significance to adopt the cylinder cleaning scheme with strong applicability and good cleaning effect to ensure the operation quality of the whole internal combustion engine.

The traditional cleaning of the cylinder block of internal combustion engine mainly includes: manual way: the cylinder block is fixed by rotating frame or bracket above the cleaning puddle, and the high-pressure spray gun is used manually to clean the cylinder block; Special cleaning machine: the use of reciprocating or through the cleaning machine to clean the cylinder block; Cleaning room: adopt single type cleaning room to clean the cylinder automatically or manually.

Cleaning: in order to ensure the cleanliness of the cylinder block, eliminate the rust during the assembly or inventory of the cylinder block to affect the quality of products and installation, so the cylinder block must be reasonably arranged cleaning, cleaning and rust prevention process. The cylinder block is fixed on the rotating frame by fastening bolts, and the mechanical power is turned around 360° around the axis. The equipment control system has control functions such as motor overload, alarm, interlocking of moving parts, emergency stop of loading and unloading station, etc., which are used for cleaning the series of cylinder blocks.

Main cleaning process: manual feeding, positioning and clamping into automatic cleaning room 360. Automatic rotary cleaning bow open mobile automatic into the manual cleaning room (close the mobile knife manual high-pressure repair, blow off the surface and cavity residual liquid, compressed air dry, open automatic discharge and feeding.)

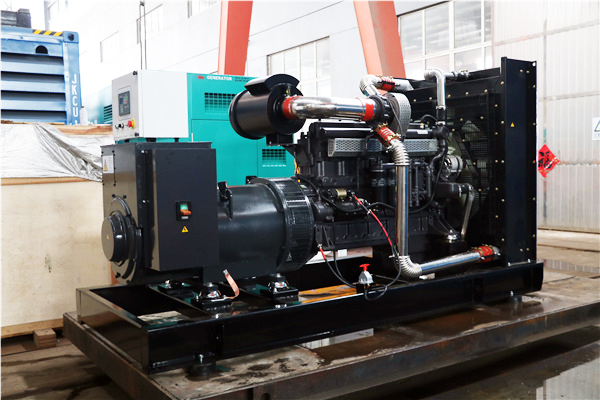

Jiangsu Meao Power Technology Co., Ltd. focuses on the development and manufacture of diesel generator sets, and has accumulated rich experience in manufacturing and service in this field. As a professional generator manufacturer, MEAOPOWER attaches great importance to product development, innovation and service quality, and maintains close strategic cooperation with famous domestic and international enterprises such as Cummins, Perkins, Doosan, Yuchai, Weichai, Shangchai, Wuxi Wandi, Lillesomer, Stanford, Marathon and so on.