Blog

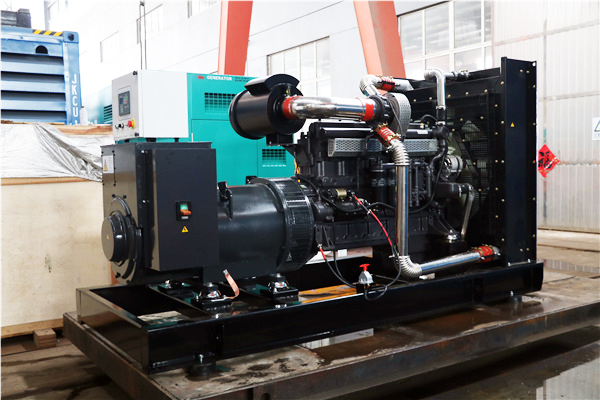

Inspection and repair of cummins generator radiator (water tank)

The main failure form of cummins diesel generator radiator (water tank) is water leakage.

The main reasons are: in the work, chongqing Cummins generator unit fan blade broken or tilt, broke the radiator water pipe; The radiator (water tank) is not firmly fixed on the support. The radiator is damaged by large vibration in the work; In winter, the water tank is frozen and cracked because of water storage, and the impurities in cooling water form scale in the radiator pipe, so that the pipe wall is corroded and broken.

1. Check the leakage of Cummins generator set

Generally speaking, the radiator (water tank) after cleaning, and then water leakage check. During the check, you can use the following two methods.

(1) the chongqing Cummins generator set radiator (water tank) inlet and outlet plug, from the overflow pipe or water plug part of the installation of a joint, into 0.15~0.03 KGF/C square meter compressed air, the generator set radiator into the pool. If there are bubbles, it is the place of leakage.

(2) Check with irrigation method. When checking, plug the inlet and outlet of the diesel generator radiator (water tank). After filling the inlet with water, observe whether the water leaks. In order to facilitate the discovery of small cracks, you can apply a certain pressure in the radiator or vibrate the radiator slightly, and then observe carefully.

2. welding repair radiator

Soldering repair of radiators usually adopts tin welding method. Before welding, the grease should be wiped clean at the welding place, and then use a scraper to scrape out a new metal layer, and then heat it properly, and then soak it in zinc oxide solution after luo Iron is heated, and then stick to solder. After bonding, the weld is repaired flat, and the zinc oxide around the weld is washed with hot water to prevent corrosion.

(1) on the welding repair, sewer room, sewer room leakage is not large, can be directly repaired with solder, such as large leakage, with copper skin welding repair. When welding, one side of the copper skin and the leak is first coated with a layer of solder, and the copper skin is placed in the water leak, and then the luo Iron is heated externally, so that the solder melts, and the surrounding welding is firmly.

(2) the welding repair of the radiator water pipe if the outer water pipe of the radiator is broken and the breach is not large, the radiator fin near the water pipe can be torn off a little with needle-nosed pliers, and directly repaired with solder. If the hole is very large or the middle water pipe leaks, it should be based on the specific situation, respectively, using the method of clamping pipe, blocking pipe, taking over and changing pipe flexible processing. However, the number of stuck pipes and blocked pipes should not exceed 10% of the number of main pipes, so as not to affect the heat dissipation effect of the radiator.

A. Card pipe: when the outer water pipe of cummins generator radiator (water tank) is broken, or the water pipe is broken on the back, the method of card pipe can be welded and repaired. The method is to tear the radiator near the broken water leakage pipe, cut off a section of broken water leakage pipe, and then the fracture of the lower water pipe and the upper water pipe near the position of the upper water chamber.

B. Pipe repair: if the tear of the outer water pipe is large and cannot be repaired by soldering, repair it by pipe repair. When the tube is filled, a layer of thin solder shall be plated on one side of the selected copper skin and the leak place respectively, and the thin copper skin shall be glued to the leak place, and its edge shall be welded firmly with a heated iron.

C. in tube: , water chamber and cracking desoldering on both ends of the conduit, and internal plastic, with a copper flat bar (its cross section was slightly smaller than the pipe diameter and slightly longer than the pipe), heated to dark red inserted inside the pipe, water pipe and the heat sink desoldering, vise grip the pipe ends and the copper bar, along the direction of the heat sink flanging, and then put one new water pipe, copper bar Install the water pipe back into the radiator, draw out the copper strip, and weld the two ends of the new water pipe and the upper and the sewer with solder.

If the middle water pipe of cummins generator set radiator is broken, it is necessary to remove the upper and lower water chamber with blowtorch flame heating after welding, and the two ends of the broken water pipe are welded, and the upper and lower water chamber are welded.

Jiangsu Meao Power Technology Co., Ltd. focuses on the development and manufacture of diesel generator sets, and has accumulated rich experience in manufacturing and service in this field. As a professional generator manufacturer, MEAOPOWER attaches great importance to product development, innovation and service quality, and maintains close strategic cooperation with famous domestic and international enterprises such as Cummins, Perkins, Doosan, Yuchai, Weichai, Shangchai, Wuxi Wandi, Lillesomer, Stanford, Marathon and so on.