Blog

Perkins generator components and unit routine maintenance

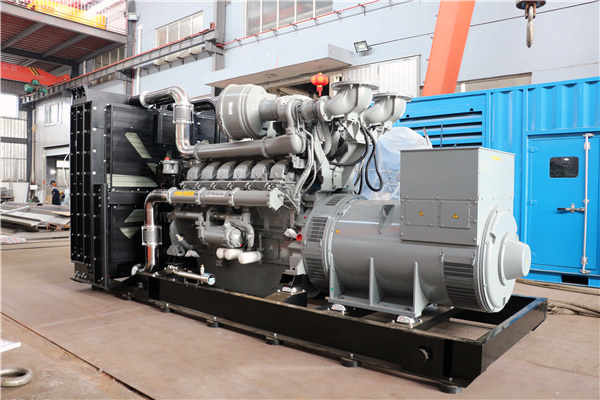

Of magnetic fields generated by the generator rotor, and installed on the outside of the stator, rotor and voltage regulator, and equipment before and after the end cap, and other various parts, daily generator used to pay maintenance, boot before running to check the amount of water and oil, also check whether choose the leakage, and regularly check the fastening and corrosion condition of parts, Here is a detailed introduction.

One, the components of the generator

1.The function of the rotor is to produce a magnetic field. The rotor consists of claw pole, yoke, excitation winding, slip ring, rotor shaft and so on.

2. The stator is installed outside the rotor, and the front and back end cover of the generator is fixed together, when the rotor in its internal rotation, the stator windings caused by magnetic flux changes, the stator windings will produce alternating induction electromotive force.

3. Rectifier The function of a rectifier is to change the three-phase alternating current of the stator windings into direct current. The rectifier consists of a rectifier plate and a rectifier diode.

4.The voltage regulator regulates the output voltage of the alternator.

5. End cover and brush assembly end cover is divided into front cover and rear cover, supporting the role of rotor, stator, rectifier and brush assembly. The rear cover is equipped with a brush assembly. The brush assembly consists of a brush, a brush rack and a brush spring. The role of the brush is to introduce power to the excitation winding through the slip ring. The two brushes are respectively installed in the hole of the brush frame, and maintain contact with the slip ring by means of spring pressure.

Two. Daily maintenance of generators

1. Check whether the gasoline in the tank is sufficient.

2. Check the oil switch and oil pipeline whether there is oil leakage phenomenon.

3. Check whether the oil level is between the oil ruler mesh grid.

4. Observe the oil quality and determine whether it needs to be replaced.

5. Check whether the starting battery voltage is above 12V, and observe whether the appearance of the battery is damaged and leaks.

6. Standby generator captain, the starting battery will lose power due to self-discharge. Please charge the battery with an external charger.

7. Check the oil discharging screw, sealing ring and rubber ring. If damaged, please replace immediately.

8. The generator in the first 20 hours (or a month) after the oil should be replaced immediately. The oil must be changed after every 100 hours (or six months) of use. (For harsh environment, it is necessary to increase the number of times, using the viscosity of SAE10W30, API grade SG, SH, SJ or higher cleaning oil)

9. The generator every 50 hours (or three months) to clean the air filter. (Increase cleaning times in harsh environment and replace if necessary)

10. Do not start the engine when there is no air filter, because it will produce excessive gas and make the cylinder wear.

11. Check the generator regularly and fill in the record truthfully. It is strictly forbidden to fill in, miss out and fill in without checking.

12. The inspection record form shall be filled in from the first ten days of this month for regular inspection.

Jiangsu Meiao Power Technology Co., Ltd. is an important manufacturer of diesel generators. Us ao-generator set manufacturers mainly manufacture and sell diesel generator sets, the power of generator sets is 3-3000KW, mobile station is 24-600KW, Marine emergency diesel generator set 24-800KW, gas generator set, heavy oil generator set and all kinds of imported series, special series (trailer, silent speaker, mobile lighthouse, container, etc.) diesel generator Group at the same time engaged in generator set maintenance and generator set accessories after-sales service.